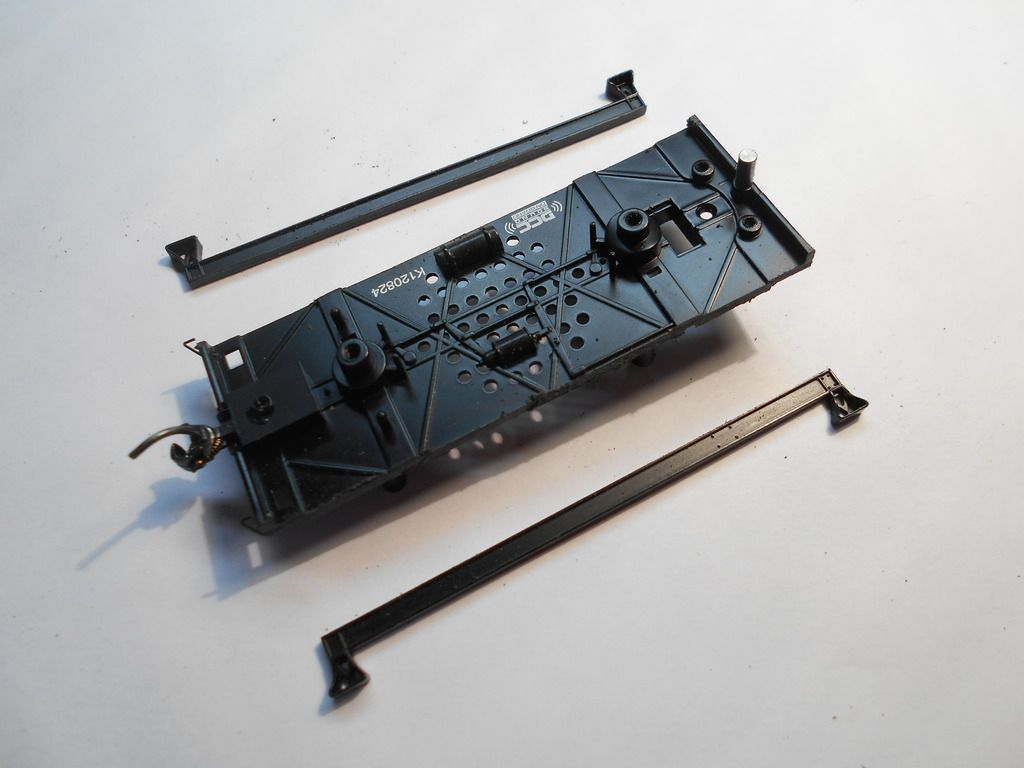

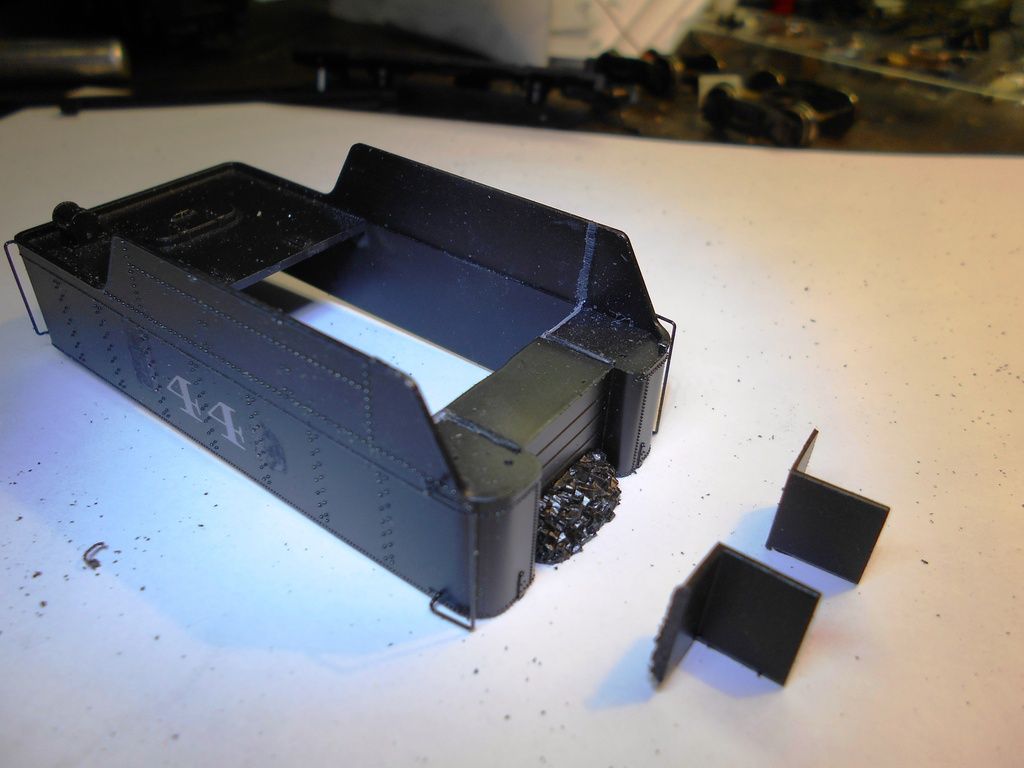

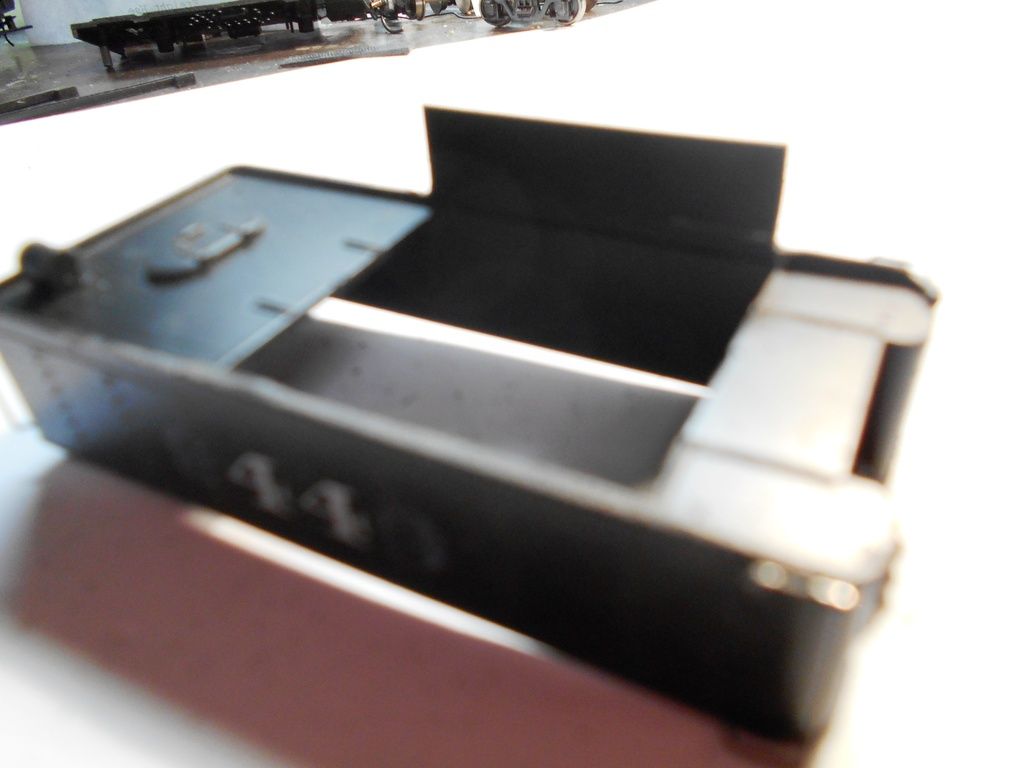

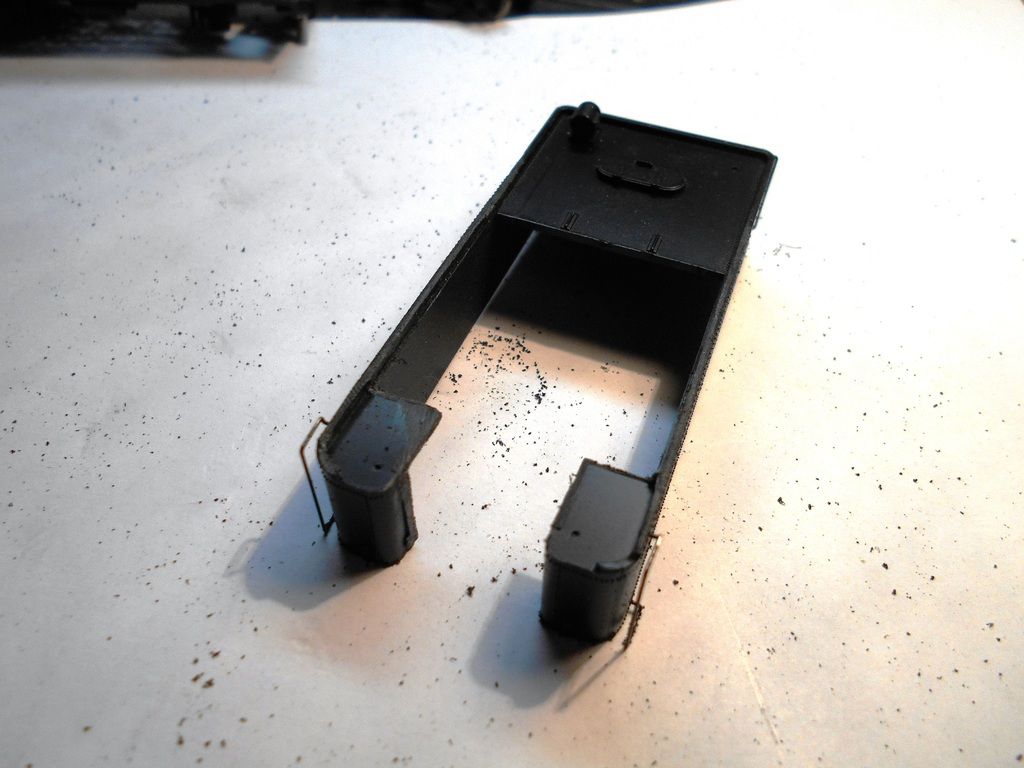

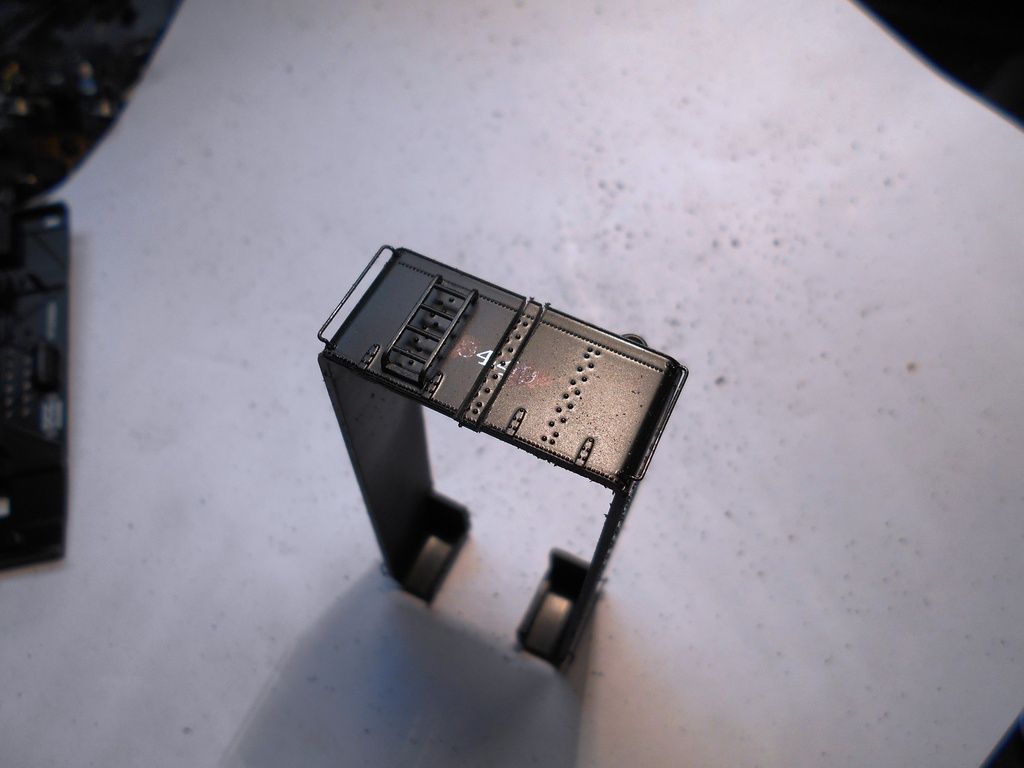

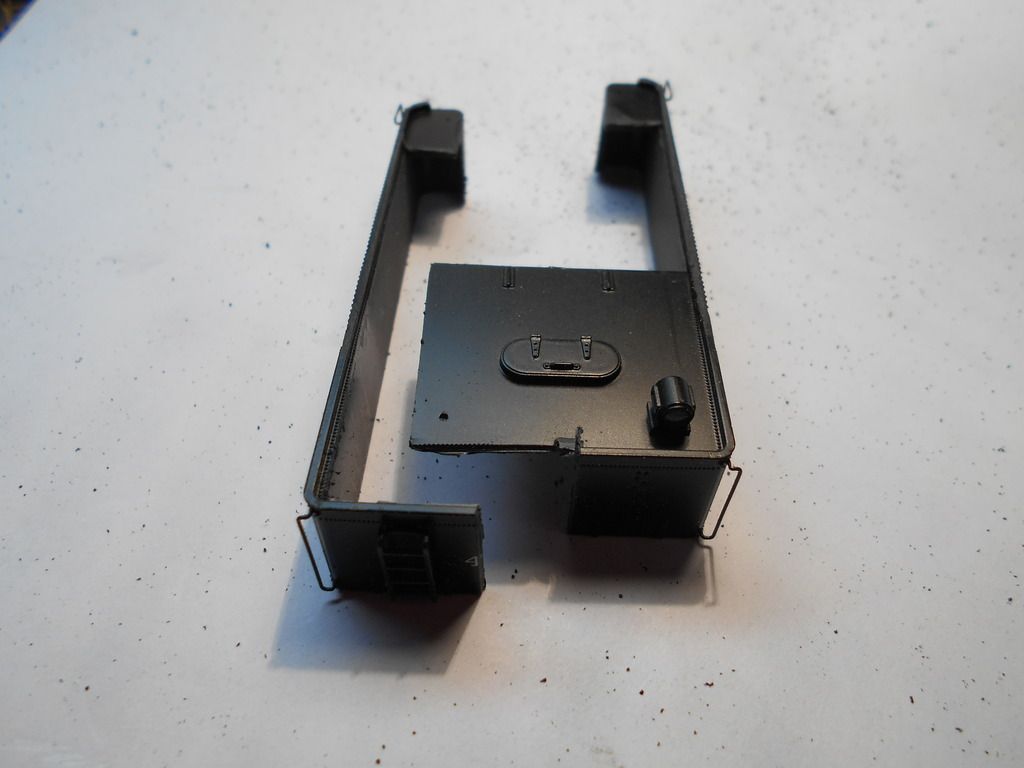

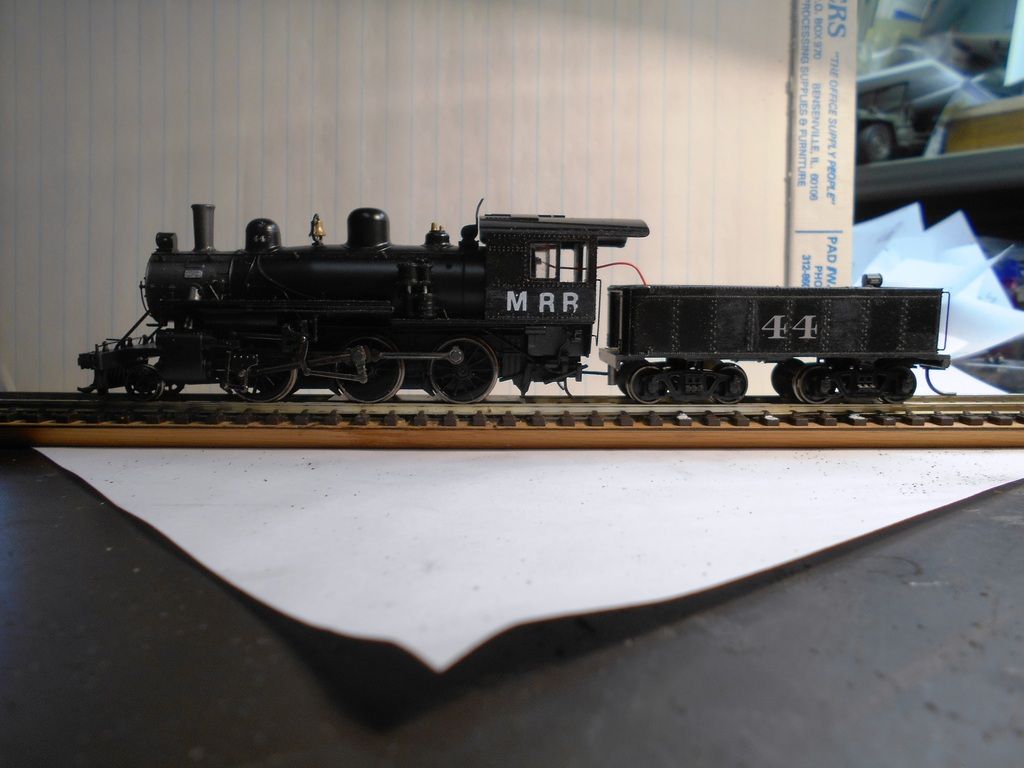

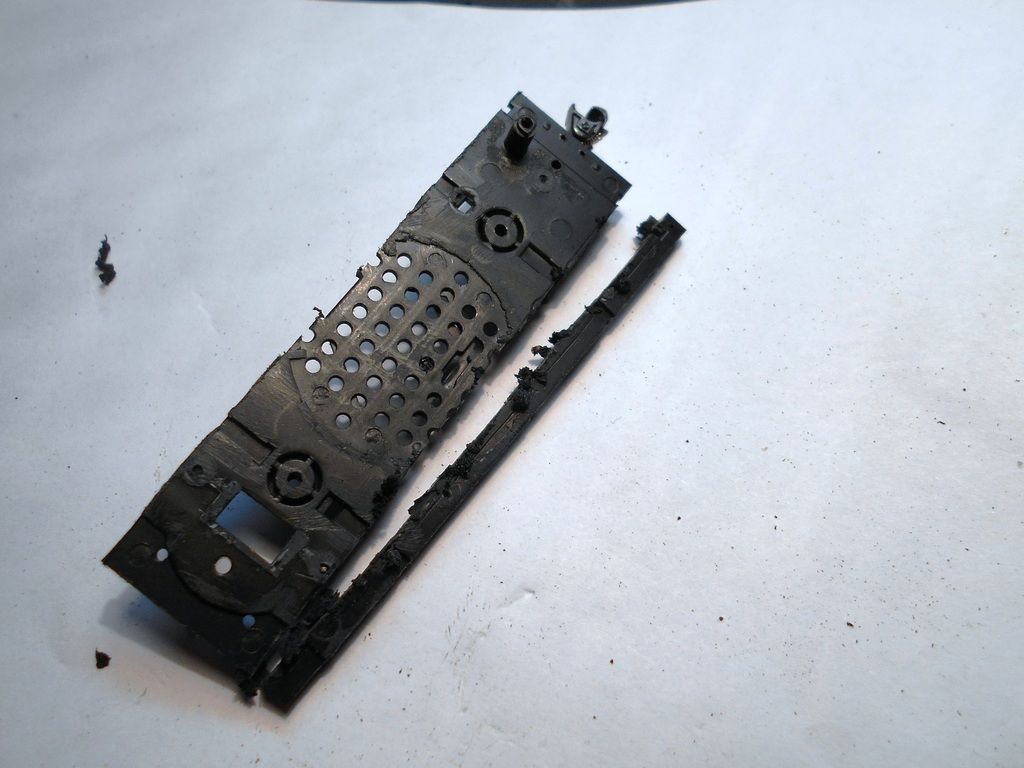

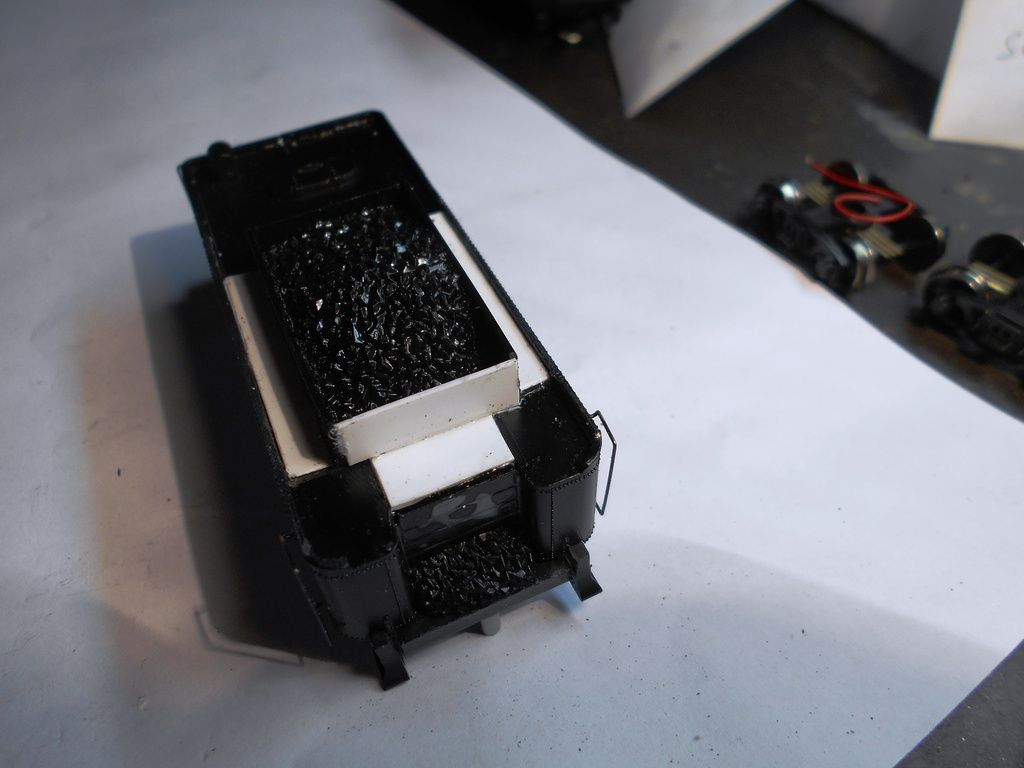

Rich - I installed a Tsunami TSU-1000 in my recently "narrowed tender body" of the B'mann Mogul. It works fine. If your tender is stock, there is plenty of room. The only modifications will be to cut off the plastic "pillars" the stock decoder was mounted on. Use double sided tape to secure board. Do not cut off the "pillar" that holds the rear light in position. You will have to cut the LED for the rear light off the OEM board. Then mount the board to the "pillar". You will need 2 3300 ohm resistors for the lights, as the Tsunami board is set up for 12v bulbs. I mounted these resistors up inside the top rear of the tender. You will be very pleased with the type and quality of sounds. Good luck, Dave

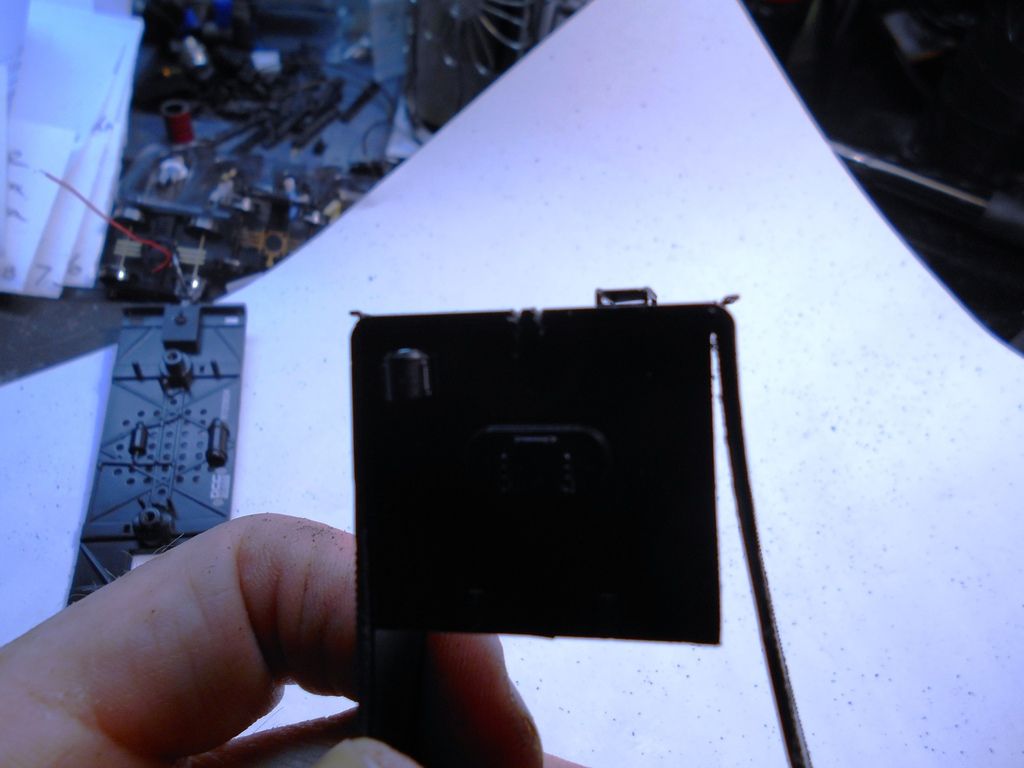

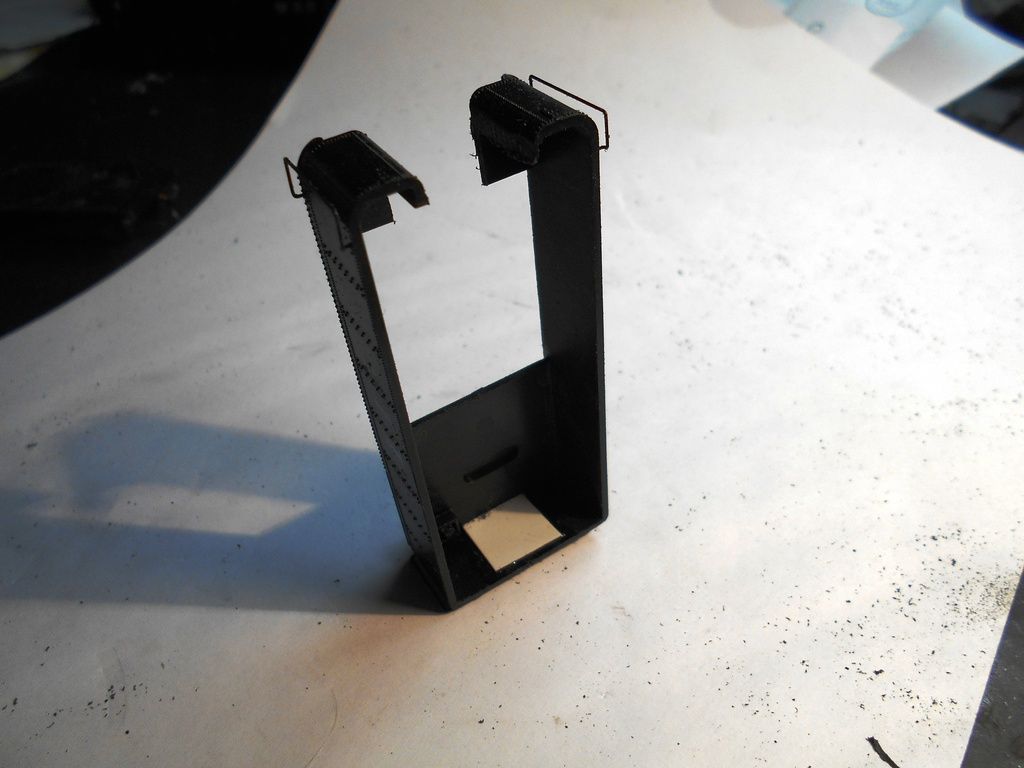

Almost forgot, you may want to put a small amount of glue around the speaker rim, as the 2 metal clips do not have a tight hold onto the speaker. Mine was very loose when I disassembled the tender. The clips a very soft, so not much pressure is put onto the speaker frame.

Almost forgot, you may want to put a small amount of glue around the speaker rim, as the 2 metal clips do not have a tight hold onto the speaker. Mine was very loose when I disassembled the tender. The clips a very soft, so not much pressure is put onto the speaker frame.