Problem solved. Found a couple of problem areas.

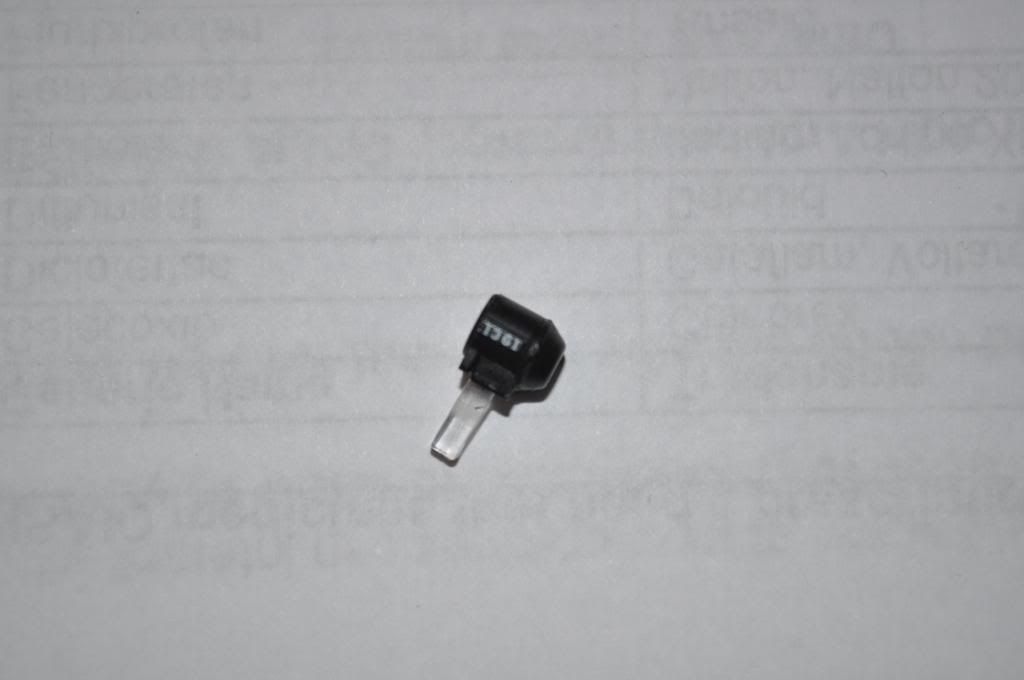

First, I found the axles were not making good contact with the metal side piece. Cleaned that off and scraped some paint away form the side piece. Next, the brass contact piece was not making good contact with the metal side piece. Again, scraped some paint away on the side piece. Much better.

Next, I soldered wires between the metal contacts to the small pcb board that is under the truck, and wires to the decoder. This eliminated the brass contacts merely brushing on the pcb board, and created a better connection from the trucks/wheels to the decoder. Would be a good suggestion for future production models, not that I see that happening.

Anyways, she is running great as I write. Thanks for everyone's advice in getting me through this conversion.

Ted

First, I found the axles were not making good contact with the metal side piece. Cleaned that off and scraped some paint away form the side piece. Next, the brass contact piece was not making good contact with the metal side piece. Again, scraped some paint away on the side piece. Much better.

Next, I soldered wires between the metal contacts to the small pcb board that is under the truck, and wires to the decoder. This eliminated the brass contacts merely brushing on the pcb board, and created a better connection from the trucks/wheels to the decoder. Would be a good suggestion for future production models, not that I see that happening.

Anyways, she is running great as I write. Thanks for everyone's advice in getting me through this conversion.

Ted