The following represents my personal experience. I am not an expert, but do like to experiment with things. Please keep this in mind as you go through this. It is long.

Over the last 6 or so years I have been working with Lithium-Ion Batteries. Early on the big scare was on about them blowing up, catching on fire, and all sorts of other dire warnings. I studied up on them at Battery University.com, with guy's who were using them on R/C cars and aircraft, and in correspondence with some of GRR friends in Germany who back then were having great success making their own battery packs. I also studied manufacturer's info and engineering sheets and found that some of them even had instructions on making battery packs. I decided to jump in and try it. Back then I made them using 18650 3.7 volt 1800 Mah or 1.8 Amp batteries from Hong Kong. There were printed circuit board (PCB) protection circuits which prevented the batteries from overcharging getting hot and rupturing or exploding. This board also protected the batteries from over discharging which would ruin the battery and prevent recharging. The boards also offered short circuit protection, which essentially shuts down the battery if the condition exists. Here is a link to one of these add on PCB's from all-battery.com

http://www.all-battery.com/ProtectionCircuitModulePCBfor4Cells14.8VLi-ionBattery-32118.aspx

Following the instructions with the PCB I built my first 14.8 Volt 1800 Mah battery pack using four cells. I used Tamiya connectors, but any connector will do. I always charge each cell individually up to full charge before building the pack. I learned that it took a very hot Iron to solder the connections to the batteries especially to the positive end. I hooked up my Tenergy Smart Charger, set it to the 14.8 volt position and waited for the batteries to blow up, or otherwise burn down my barn. To my joy it worked perfectly and during the charging period the battery pack remained cool to the touch. I made another one and used them in my Annies and Connies with great success. They are both still serviceable as I write this, proving to be far superior to my NMIH or NiCad batteries. The major (to me) pain of all this was all the soldering to the PCB and batteries. I mentioned my success on one of the major GRR forums and was promptly flamed to death about how it was impossible to do safely, and how NMIH technology was far superior! blah blah Etc. Etc. I was not discouraged and loved the low cost and good runtime using the home made packs.

Next All-battery.com came out with the 18650 Tenergy 3.7 volt 2200 Mah battery with a built in PCB in the negative end of each cell. I thought WOW! this would really reduce the amount of soldering necessary and greatly reduce the possibility of an error so I built two more packs using them. Here is a link to show a battery with the built in PCB. Care is necessary when soldering to avoid getting the negative end too hot and destroying the PCB.

http://www.all-battery.com/4pcsTenergyLi-Ion18650Cylindrical3.7V2200mAhRechargeableBatteriesWithTabs.aspx

These packs were such a success and so much better, that I got rid of my NMIH and NiCad packs altogether. I had so many inquiries I ended up doing a few clinics on making the packs, and got great raves from others who also had success. I was also flamed, beat up on, blah blah etc.etc. for doing these clinics and "endangering others". Things have changed since then and Lithium technology has become mainstream. To me the only real disadvantage of the lithium Ion batteries was that when the packs get down to the 2.5 volt threshold the undercharge circuit kicks in and shuts the battery down abruptly to prevent over discharge. This occurs without warning since the batteries perform so well there is no subtle slowing down noticeable like you get using NIMH or NiCad batteries. This would be bad news if it occurred in a long tunnel and you had to fish your loco out of it. This led to a desire for longer run time. When Tenergy came out with the 18650 2600 Mah cells I used them as well and loved the improved run time, especially noticeable over the older 1800 Mah cells. I have had one Tenergy 2600 mah pack fail due to one bad cell. It is a pain to troubleshoot because all the cells have to be disconnected to find the bad one. I do not know the cause, but it is possible I damaged it by dropping it, or had a PCB board fail.

A good friend who likes to run 4 F7's and an Alco PB (ABBBA) Pulling 13 heavy passenger cars was getting about an hour and 45 minutes run time using home made packs of 12 2600mah 3.7 volt cells connected in series to make a 14.8 volt 7800 Mah battery pack. He has grades of 3.5% He saw the GTL 3.7 volt 5300 Mah cells on Ebay and we bought some, thinking they did not have the internal PCB protection circuit. We were pleasantly surprised to find that they did have the built in PCB protection, and that they were the latest type with the PCB protection circuit enclosed within the case rather than added on the end like the Tenergy example above. At a price of $39 for twelve cells and no shipping I was amazed. You can make three 14.8 volt 5300 Mah packs for about $13 each including a connector. The Tenergy smart charger works fine with them. The run time is so good that I never run them down to a shut down using my Connies and Annies.

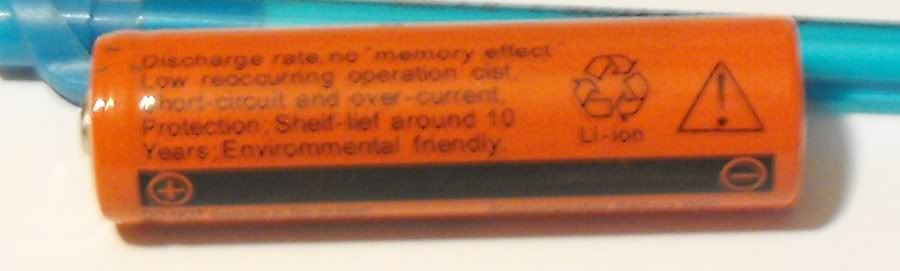

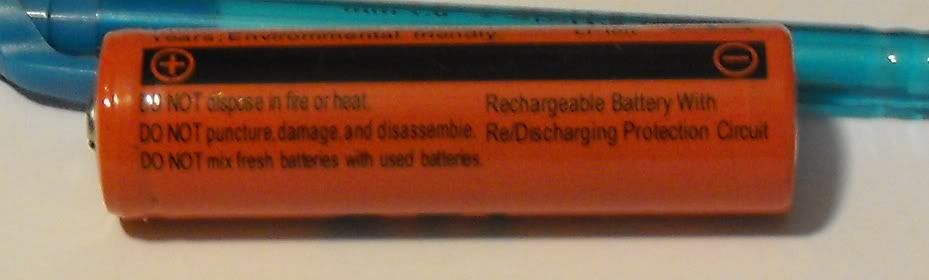

Here are the pictures of the printing on the side of the 5300 mah cells showing the information on the internal protection: Sorry about the poor quality, had to borrow a camera.

Here is a home made "Square"5300 mah pack soldered and wrapped with electrical tape. It is made to go into a U25B from a top hatch on the loco. I'm too cheap to use expensive large shrink wrap when color electrical tape is cheap at Harbor Freight. I have also built them into the fuel tanks of a couple of GP-7's using an external charging jack. The second pic shows a "flat" one to fit under the coal load on Connies & Annies.

Our testing so far indicates that the 5300 mah batteries are good quality and the protection circuits work like they are supposed to. We have only been using them for two months so time will tell if they hold up. Compared to the Tenergy Batteries the GTL's are more difficult to solder to the positive end. While I personally dislike trail cars with receivers & batteries these home made battery packs are just fine in trail cars as well.

These batteries are 18650 size and fit in commercially available battery holders (or boxes) which hold one to four cells. If you have room in your locos using these would totally eliminate the need to solder to the batteries. You would only need to solder on the connector of your choice pop the batteries in and go. This would be of great advantage if a cell failed. All you would need to do is take them out test them individually, replace the bad one and you are ready to go again. Here is the link for the battery boxes:

http://www.ledsupermall.com/diy-battery-box-for-4-18650-battery.html

I have not yet received mine and will post later about my experience with them.

Remember You MUST follow all safety rules and measures. I use a clear mask when soldering, wear a long sleeve shirt, and place the batteries in a ceramic bowl when charging. I also make sure ventilation is good. There are other rules I probably haven't mentioned. When engaging in these activities it is your responsibility to learn and follow all safety rules, procedures and instructions. I do not guarantee your results will be similar to mine or your safety. Soldering to the batteries will void any warranty.

Most of all have fun!!!

Bill

Over the last 6 or so years I have been working with Lithium-Ion Batteries. Early on the big scare was on about them blowing up, catching on fire, and all sorts of other dire warnings. I studied up on them at Battery University.com, with guy's who were using them on R/C cars and aircraft, and in correspondence with some of GRR friends in Germany who back then were having great success making their own battery packs. I also studied manufacturer's info and engineering sheets and found that some of them even had instructions on making battery packs. I decided to jump in and try it. Back then I made them using 18650 3.7 volt 1800 Mah or 1.8 Amp batteries from Hong Kong. There were printed circuit board (PCB) protection circuits which prevented the batteries from overcharging getting hot and rupturing or exploding. This board also protected the batteries from over discharging which would ruin the battery and prevent recharging. The boards also offered short circuit protection, which essentially shuts down the battery if the condition exists. Here is a link to one of these add on PCB's from all-battery.com

http://www.all-battery.com/ProtectionCircuitModulePCBfor4Cells14.8VLi-ionBattery-32118.aspx

Following the instructions with the PCB I built my first 14.8 Volt 1800 Mah battery pack using four cells. I used Tamiya connectors, but any connector will do. I always charge each cell individually up to full charge before building the pack. I learned that it took a very hot Iron to solder the connections to the batteries especially to the positive end. I hooked up my Tenergy Smart Charger, set it to the 14.8 volt position and waited for the batteries to blow up, or otherwise burn down my barn. To my joy it worked perfectly and during the charging period the battery pack remained cool to the touch. I made another one and used them in my Annies and Connies with great success. They are both still serviceable as I write this, proving to be far superior to my NMIH or NiCad batteries. The major (to me) pain of all this was all the soldering to the PCB and batteries. I mentioned my success on one of the major GRR forums and was promptly flamed to death about how it was impossible to do safely, and how NMIH technology was far superior! blah blah Etc. Etc. I was not discouraged and loved the low cost and good runtime using the home made packs.

Next All-battery.com came out with the 18650 Tenergy 3.7 volt 2200 Mah battery with a built in PCB in the negative end of each cell. I thought WOW! this would really reduce the amount of soldering necessary and greatly reduce the possibility of an error so I built two more packs using them. Here is a link to show a battery with the built in PCB. Care is necessary when soldering to avoid getting the negative end too hot and destroying the PCB.

http://www.all-battery.com/4pcsTenergyLi-Ion18650Cylindrical3.7V2200mAhRechargeableBatteriesWithTabs.aspx

These packs were such a success and so much better, that I got rid of my NMIH and NiCad packs altogether. I had so many inquiries I ended up doing a few clinics on making the packs, and got great raves from others who also had success. I was also flamed, beat up on, blah blah etc.etc. for doing these clinics and "endangering others". Things have changed since then and Lithium technology has become mainstream. To me the only real disadvantage of the lithium Ion batteries was that when the packs get down to the 2.5 volt threshold the undercharge circuit kicks in and shuts the battery down abruptly to prevent over discharge. This occurs without warning since the batteries perform so well there is no subtle slowing down noticeable like you get using NIMH or NiCad batteries. This would be bad news if it occurred in a long tunnel and you had to fish your loco out of it. This led to a desire for longer run time. When Tenergy came out with the 18650 2600 Mah cells I used them as well and loved the improved run time, especially noticeable over the older 1800 Mah cells. I have had one Tenergy 2600 mah pack fail due to one bad cell. It is a pain to troubleshoot because all the cells have to be disconnected to find the bad one. I do not know the cause, but it is possible I damaged it by dropping it, or had a PCB board fail.

A good friend who likes to run 4 F7's and an Alco PB (ABBBA) Pulling 13 heavy passenger cars was getting about an hour and 45 minutes run time using home made packs of 12 2600mah 3.7 volt cells connected in series to make a 14.8 volt 7800 Mah battery pack. He has grades of 3.5% He saw the GTL 3.7 volt 5300 Mah cells on Ebay and we bought some, thinking they did not have the internal PCB protection circuit. We were pleasantly surprised to find that they did have the built in PCB protection, and that they were the latest type with the PCB protection circuit enclosed within the case rather than added on the end like the Tenergy example above. At a price of $39 for twelve cells and no shipping I was amazed. You can make three 14.8 volt 5300 Mah packs for about $13 each including a connector. The Tenergy smart charger works fine with them. The run time is so good that I never run them down to a shut down using my Connies and Annies.

Here are the pictures of the printing on the side of the 5300 mah cells showing the information on the internal protection: Sorry about the poor quality, had to borrow a camera.

Here is a home made "Square"5300 mah pack soldered and wrapped with electrical tape. It is made to go into a U25B from a top hatch on the loco. I'm too cheap to use expensive large shrink wrap when color electrical tape is cheap at Harbor Freight. I have also built them into the fuel tanks of a couple of GP-7's using an external charging jack. The second pic shows a "flat" one to fit under the coal load on Connies & Annies.

Our testing so far indicates that the 5300 mah batteries are good quality and the protection circuits work like they are supposed to. We have only been using them for two months so time will tell if they hold up. Compared to the Tenergy Batteries the GTL's are more difficult to solder to the positive end. While I personally dislike trail cars with receivers & batteries these home made battery packs are just fine in trail cars as well.

These batteries are 18650 size and fit in commercially available battery holders (or boxes) which hold one to four cells. If you have room in your locos using these would totally eliminate the need to solder to the batteries. You would only need to solder on the connector of your choice pop the batteries in and go. This would be of great advantage if a cell failed. All you would need to do is take them out test them individually, replace the bad one and you are ready to go again. Here is the link for the battery boxes:

http://www.ledsupermall.com/diy-battery-box-for-4-18650-battery.html

I have not yet received mine and will post later about my experience with them.

Remember You MUST follow all safety rules and measures. I use a clear mask when soldering, wear a long sleeve shirt, and place the batteries in a ceramic bowl when charging. I also make sure ventilation is good. There are other rules I probably haven't mentioned. When engaging in these activities it is your responsibility to learn and follow all safety rules, procedures and instructions. I do not guarantee your results will be similar to mine or your safety. Soldering to the batteries will void any warranty.

Most of all have fun!!!

Bill

Hope to see you there!!

Hope to see you there!!