Gene- Less than 1 minute to make one spring. 1 to 2 minutes to fine tune it on a car. I use a piece of track

mounted on hardwood base for testing. Tilted to 1 percent grade, car should not roll on its own. Tilted to

2 percent grade, car should start and roll on its own. No push required. This keeps all cars similar. My cars

are all at or slightly above NMRA weight guides. Note I use only one truck per car with the spring.

Car Weight: Cars that are too light, relatively speaking, will have trouble assuring a good couple.

This can happen with any brand coupler.

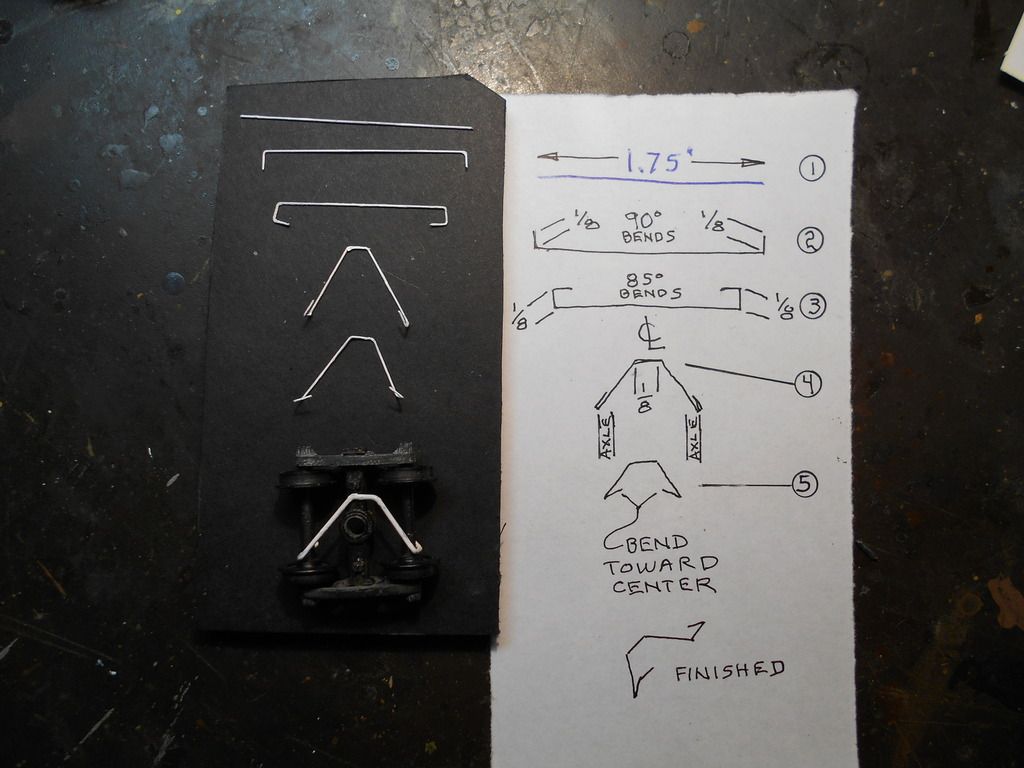

No glue required. The tension of the V shape and the slight twist at the ends of the wire "legs"

keeps them in place. Mounted on top or bottom makes no difference. Never had one come off yet.

In fact, I have to use tweezers to remove them, one axle at a time.

Len - Thanks again for the lead on posting pics. Was really easy after first one. I noticed a recent post

that suggested only 1 pic be attached with originating posting. Then I should reply to that posting and

include the remaining pics. What would be the reason for doing this? Thanks, Dave

mounted on hardwood base for testing. Tilted to 1 percent grade, car should not roll on its own. Tilted to

2 percent grade, car should start and roll on its own. No push required. This keeps all cars similar. My cars

are all at or slightly above NMRA weight guides. Note I use only one truck per car with the spring.

Car Weight: Cars that are too light, relatively speaking, will have trouble assuring a good couple.

This can happen with any brand coupler.

No glue required. The tension of the V shape and the slight twist at the ends of the wire "legs"

keeps them in place. Mounted on top or bottom makes no difference. Never had one come off yet.

In fact, I have to use tweezers to remove them, one axle at a time.

Len - Thanks again for the lead on posting pics. Was really easy after first one. I noticed a recent post

that suggested only 1 pic be attached with originating posting. Then I should reply to that posting and

include the remaining pics. What would be the reason for doing this? Thanks, Dave