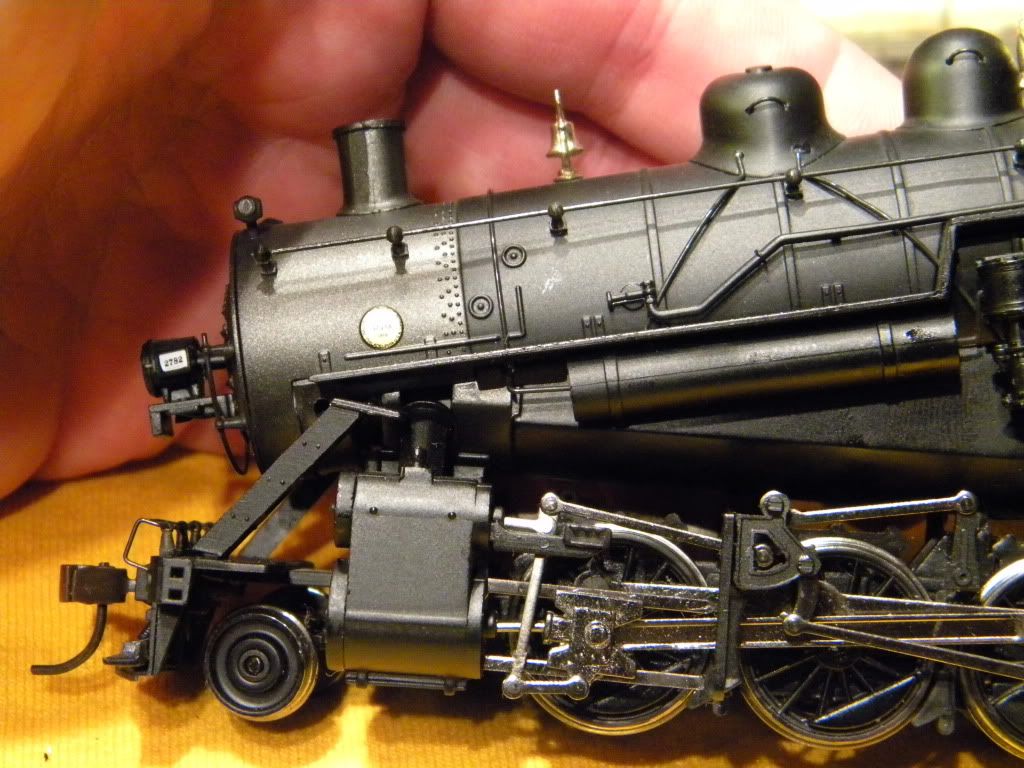

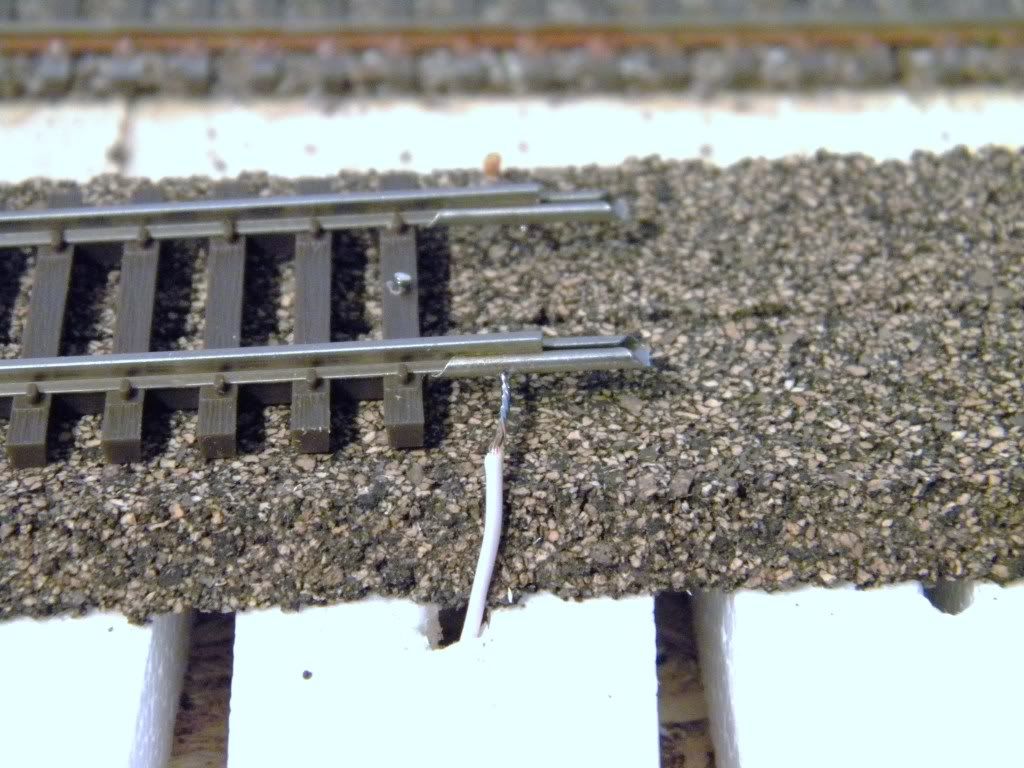

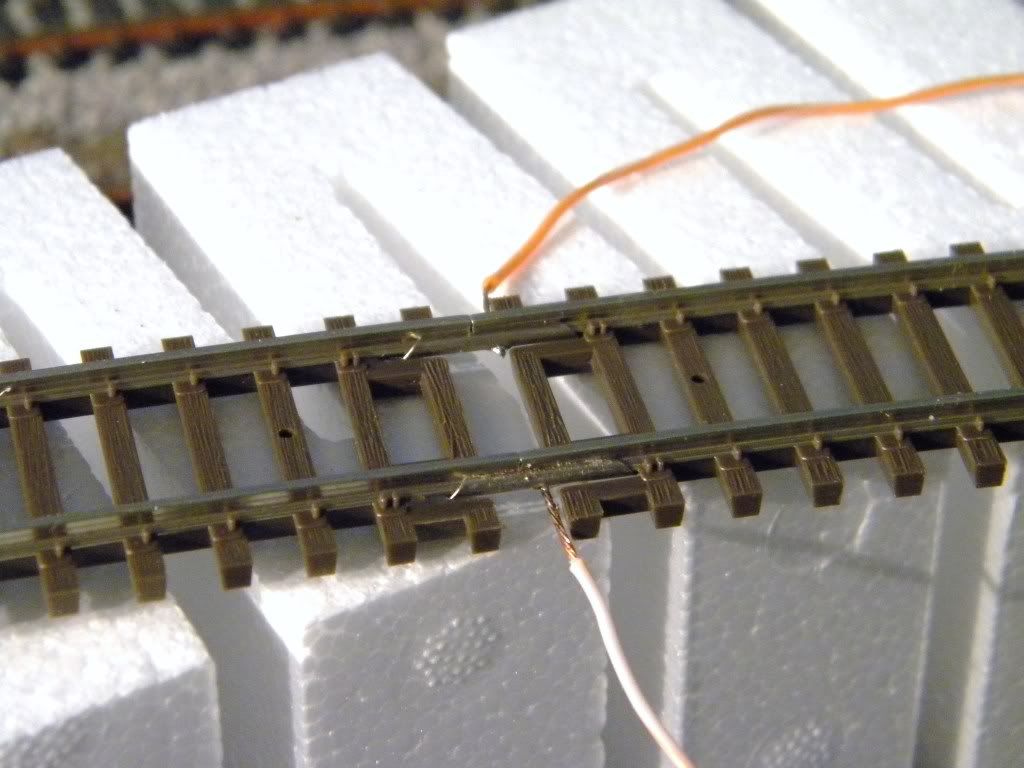

Not sure of the proper nomenclature. I am installing a turntable. I don't have much space to work with. I am using the Atlas turntable (nice and small and easy to install).

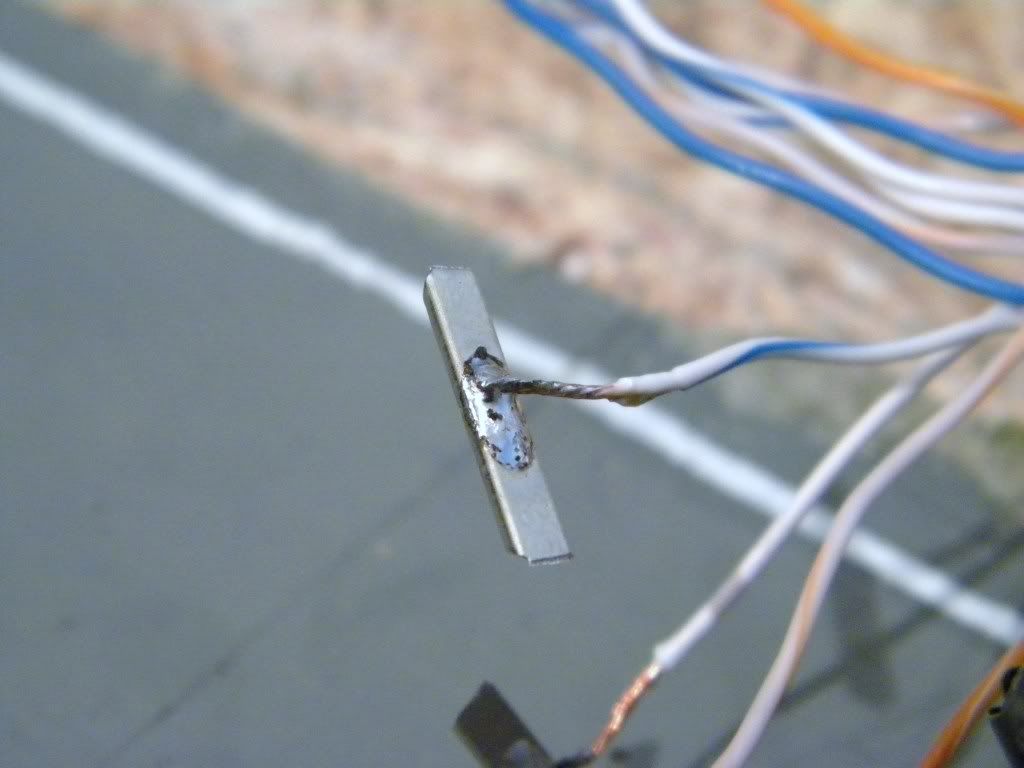

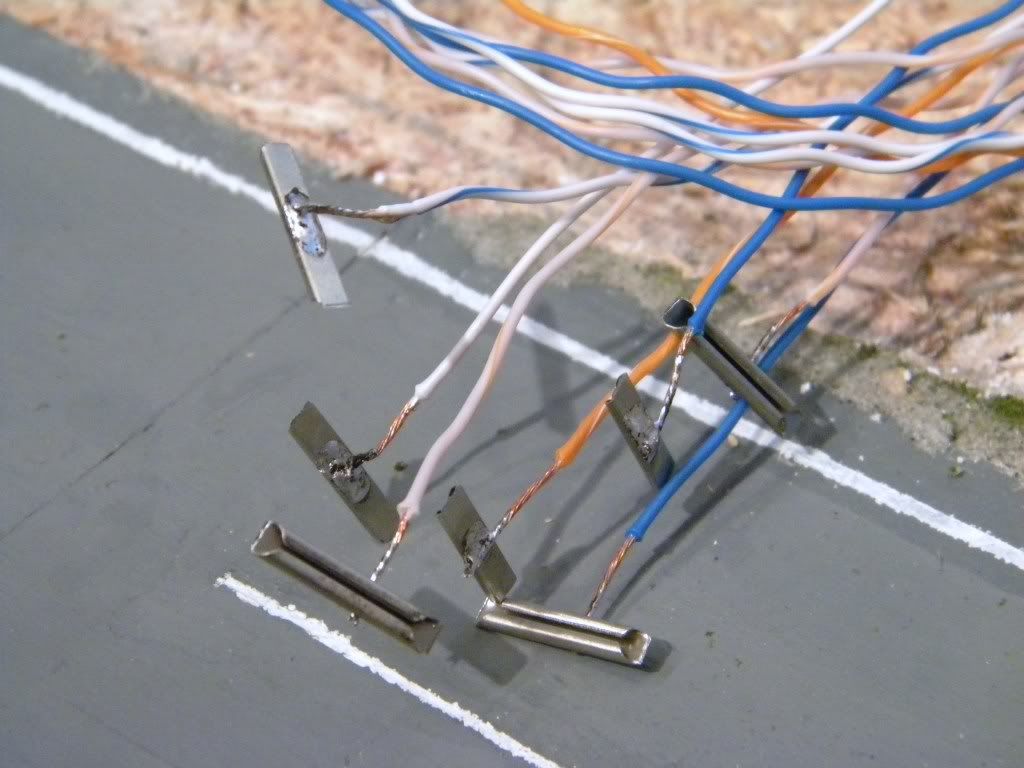

I can tell already I won't have room for adding bumpers. I was wondering if anyone has ever made some kind of small device that solders or glues to the end of the rail, as a wheel stop. I can't let my engines go for a ride to the garage floor, if my fingers slip.

Anyway, the wheel chock thing is my concern.

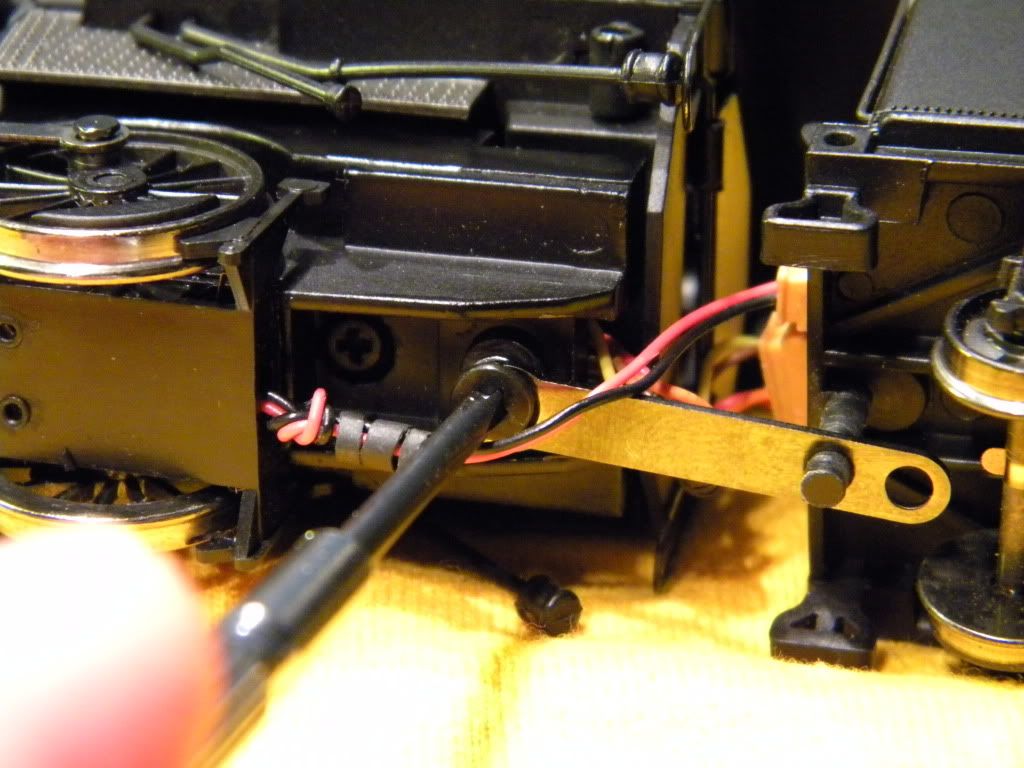

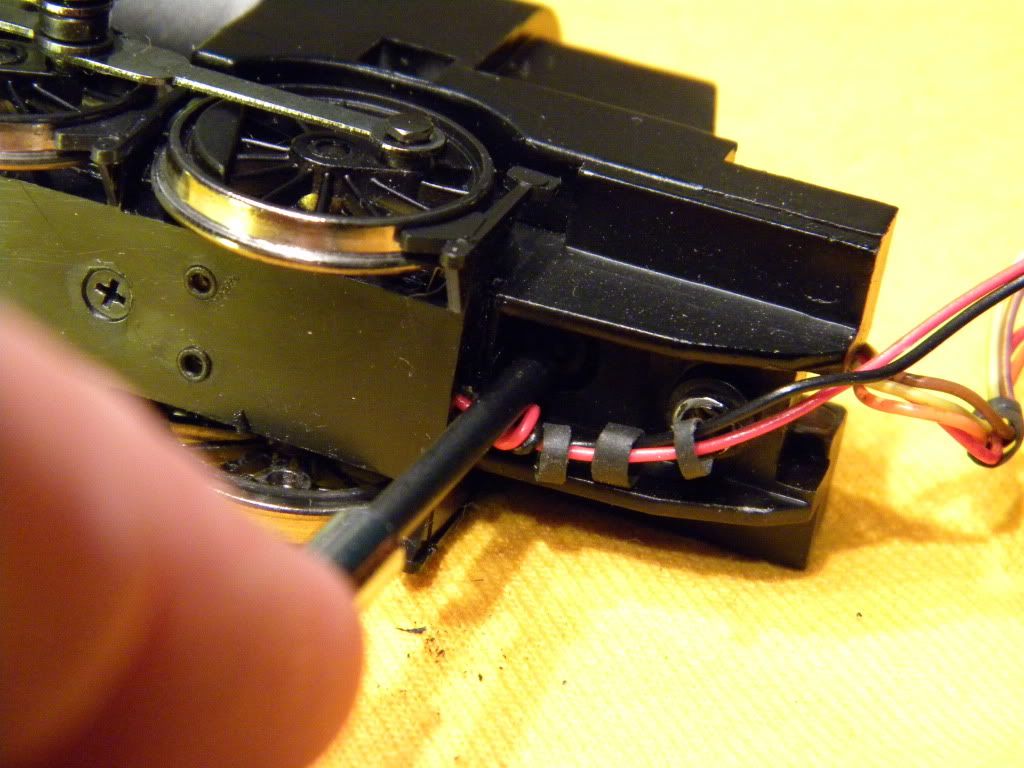

Here's a little homemade control box I made. So far I can switch on/off 4 tracks. Plan to power one more track and have a switch, or button, for the turntable motor, if/when I decide to intall one (read, if I find one cheap enough ).

).

Regards,

Jonathan

I can tell already I won't have room for adding bumpers. I was wondering if anyone has ever made some kind of small device that solders or glues to the end of the rail, as a wheel stop. I can't let my engines go for a ride to the garage floor, if my fingers slip.

Anyway, the wheel chock thing is my concern.

Here's a little homemade control box I made. So far I can switch on/off 4 tracks. Plan to power one more track and have a switch, or button, for the turntable motor, if/when I decide to intall one (read, if I find one cheap enough

).

).

Regards,

Jonathan

).

).